Hospitals, pharmacies, and patients all rely on logistics companies that deliver heat-sensitive medicines, such as insulin and vaccines, to keep them at the right temperature at every step in the transport chain.

Swiss Post and its partner Modum have built a blockchain solution to monitor the temperature of medicines at all stages of transit — right up to the moment they are handed over to the customer.

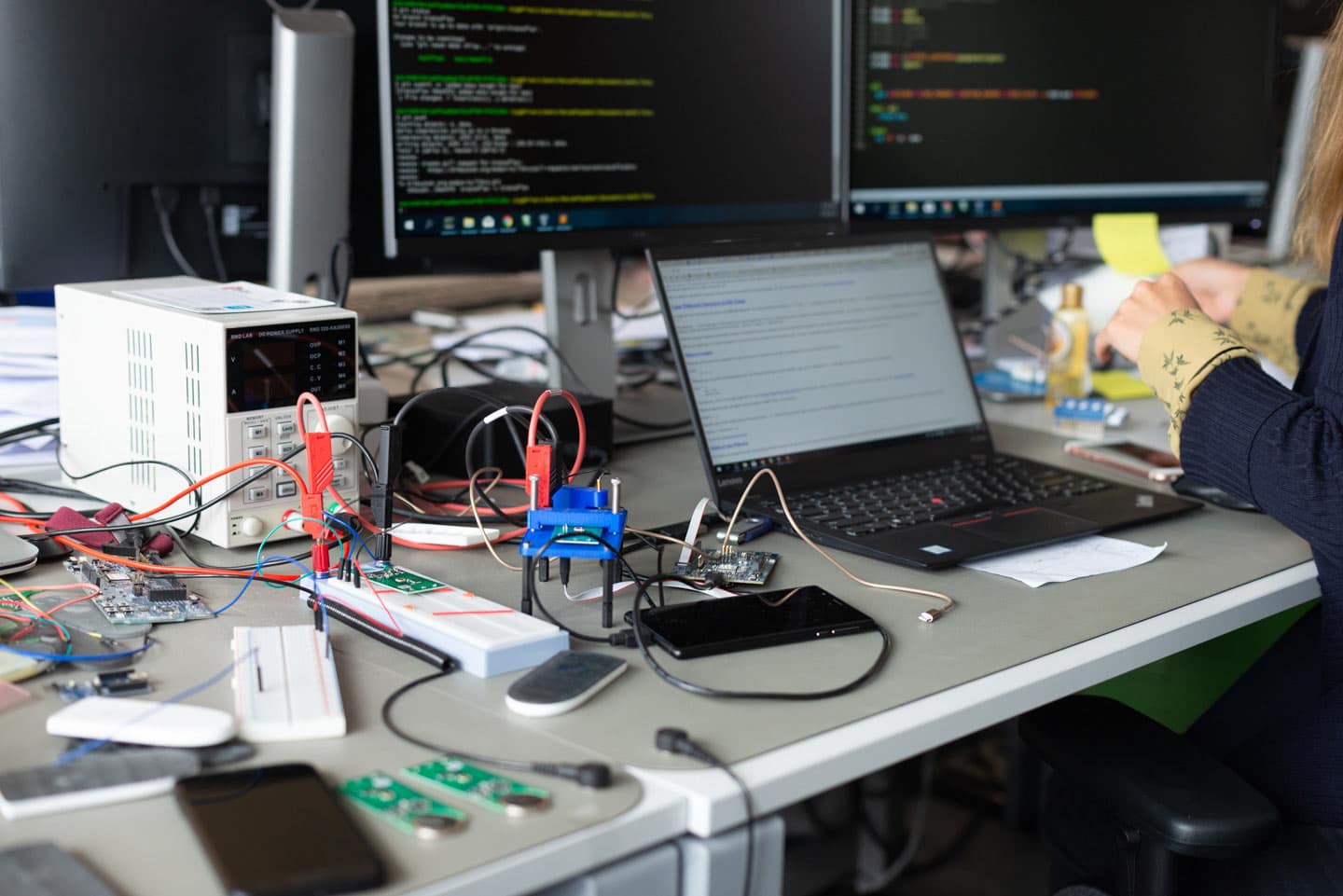

Many medicinal and pharmaceutical products have to be kept within certain temperature ranges while in transit, which may be over thousands of kilometers. To monitor the temperatures to which these products are exposed, Swiss Post uses smart transportation boxes, blockchain, and the Internet of Things (IoT).

Monitoring the Supply Chain with Blockchain and IoT

“Not many European logistics companies transport medicinal products because the requirements have become so strict,” says Thomas Wälchli. As head of Business Development and Industry Management at PostLogistics, the logistics division of Swiss Post, it was Wälchli’s job to design shipping solutions that comply with EU guidelines on Good Distribution Practice.

“We didn’t want to invest in a fleet of refrigerated vehicles to transport medicines and healthcare products,” he explains. Instead, the company decided to develop a box that can maintain a certain temperature. The ability to monitor the temperature in these boxes is new, however. In Swiss startup Modum, Swiss Post found a co-innovation partner with customers in the pharmaceutical industry that are customers of SAP. Modum created an IoT solution called MODSense, which monitors temperature.

Since trust among all parties in a supply chain is paramount, Modum and Swiss Post decided to incorporate blockchain technology as well. It enables a unique checksum of all the sensor data from the physical goods to be stored. This makes it easy to prove at any time that sensor data has not been manipulated. Using blockchain technology in this way builds trust in the digital ecosystem. Valuable information about how the goods have passed through the supply chain can be exchanged securely with everyone in it, and processes can be automated.

Since trust among all parties in a supply chain is paramount, Modum and Swiss Post decided to incorporate blockchain technology as well. It enables a unique checksum of all the sensor data from the physical goods to be stored. This makes it easy to prove at any time that sensor data has not been manipulated. Using blockchain technology in this way builds trust in the digital ecosystem. Valuable information about how the goods have passed through the supply chain can be exchanged securely with everyone in it, and processes can be automated.

MODSense uses an IoT sensor that is placed inside a package and programmed with the permitted temperature range for the content of that package. An entry to the blockchain is created, storing this information.

The sensor collects data — for example the temperature inside the package — while it is in transit, offline. At delivery, the bar code on the package is scanned, the data collected by the sensor is read, and the checksum is written to the blockchain. A smart contract in the blockchain then automatically selects one of two actions: send product again or issue the invoice.

The joint project between Swiss Post and Modum began in June 2017. The idea of asking SAP to assist Modum came later, at the end of 2017.

The joint project between Swiss Post and Modum began in June 2017. The idea of asking SAP to assist Modum came later, at the end of 2017.

“We explored how SAP Co-Innovation Lab could help build solutions on SAP Cloud Platform,” explains Hans-Joachim Odlozinski, head of SAP Co-Innovation Lab locations in Austria, Germany, Switzerland, and Africa. Following some initial discussions with Modum, SAP teamed with the startup and Swiss Post in early 2018.

Partner Enablement Adds Value for Customers and SAP

“Our model for co-innovating with customers was the basis for our collaboration with Swiss Post,” says Marc Degen, co-founder of Modum. “It was a perfect match.”

SAP Co-Innovation Lab brings partners and their ideas together within SAP so that, whenever they need to, they can draw on the expertise of different development teams at the company.

“Swiss Post and Modum had a lot of ideas from the start,” says Pascal Hagedorn, project leader at the SAP Co-Innovation Lab location in Switzerland. “We just had to define exactly what we wanted to achieve with blockchain. That is where the expertise of colleagues from SAP Innovation Center Network really helped.”

Blockchain technology from SAP was used for a proof of concept to implement the solution across the company. Experienced blockchain developers under Torsten Zube, head of SAP Innovation Center Network and Blockchain at SAP, were part of the project. “We started the pilot at the end of November 2018,” explains Wälchli.

“That is what we do at SAP Co-Innovation Lab,” says Odlozinski. “We work with partners—here it was Modum—to develop a proof of concept and enable them to implement it for the customer, in this case Swiss Post.” Safeguarding intellectual property rights is a priority. “Partners own the rights to the solutions they build,” he adds.

SAP Global Track and Trace

Degen describes the collaboration with SAP as very close. He says it was underpinned by a joint vision of companies quickly and reliably creating digital innovations on flexible cloud stacks.

“Being able to work with state-of-the-art solutions, such as the Hyperledger Fabric service on SAP Cloud Platform, makes SAP attractive to startups because you don’t have to read up on SAP stacks before you get started.”

Degen and the team at Modum used invitations to events such as SAPPHIRE NOW in 2018 and Outside the Block in Berlin to collect early feedback on the solution from partners and customers. “These events also helped us get our name out there, and that’s not easy for a start-up,” he says.

Degen and the team at Modum used invitations to events such as SAPPHIRE NOW in 2018 and Outside the Block in Berlin to collect early feedback on the solution from partners and customers. “These events also helped us get our name out there, and that’s not easy for a start-up,” he says.

Swiss Post is building on its work with Modum and SAP. It is looking at how food distributors might also benefit from the new blockchain-IoT solution. “The main advantage of the solution is that selective information can be accessed securely by every party in the supply chain,” explains Wälchli.

Hagedorn adds, “This makes it an attractive extension to other SAP solutions for logistics, such as SAP Global Track and Trace. Under our co-innovation project, we are currently working with Modum on how to integrate it into SAP’s business process world.”

Images via Swiss Post.